Bridgestone Vs. Michelin Tires – Who’s the Boss

Bridgestone and Michelin are the two industry giants of the tire market.

The crankshaft position sensor is one of the car’s vital components. It is very small but has great importance. Sensing the crankshaft’s position and speed makes the engine run smoothly. This data greatly benefits the ECU as it helps regulate fuel injection and ignition timing. The crankshaft position sensor is crucial for the right engine performance and economy in modern vehicles.

Let’s explore what a crankshaft position sensor is before going into any further detail.

A crankshaft sensor is a small electronic item in your vehicle’s engine. Its primary role is to keep track of the crankshaft’s position and rotational speed. The crankshaft is one of the most important elements in engine operation and assists in turning the pistons. The sensor passes this data to the engine control unit (ECU).

The crankshaft position sensor discovers the crankshaft’s position and speed through a magnet or an optical sensor. It comprises a gear or a wheel that rotates along the crankshaft. The sensor generates a signal each time a tooth is passed by the rotation of the crankshaft. This signal is transmitted to the ECU, which uses the data to alter the timing of fuel injection and ignition. This exact timing causes the engine to run smoothly and without any difficulties.

Here are the main sensors of the crankshaft position failure:

Monitoring the Position and Rotational Speed of the Crankshaft: This sensor recognizes the position where the crankshaft is and how fast it turns. So, the engine’s piston moves perfectly.

Communicating with the Engine Control Unit (ECU): It transmits data in real-time to the engine’s processor, enabling the engine to control different engine functions better.

Role in Ignition Timing and Fuel Injection: ECU uses the sensor data to compute exactly the timing for ignition and to figure the amount of fuel that will go into the engine for efficient and smooth engine function.

Here are the symptoms of crankshaft position sensor failure. Let’s have a look:

A faulty crankshaft sensor may cause the engine to misfire or run unevenly. The sensor cannot provide the right data, resulting in incorrect fuel and ignition timing.

If the sensor is not in good working condition, the ECU will not be able to get the appropriate data needed for the engine to begin efficiently. Thus, the engine will take time to crank or will not start.

A bad crankshaft position sensor signal often appears as the check engine warning. ECU sensed the failure and informed the driver by lighting this icon on the dashboard.

If the sensor generates erroneous data, the ECU cannot adjust the fuel injection and ignition timing to achieve an ideal balance. This results in fuel waste, lowering the car’s overall fuel capacity.

A sensor failure may even lead to the engine stalling under unpredictable circumstances or shutting down completely. This is because the ECU cannot obtain accurate information to maintain the engine’s normal performance.

There are some crucial steps to be done when diagnosing problems with the crankshaft position sensor. First, employ diagnostic tools like an OBD-II scanner, which helps you to identify error codes such as P0335 and P0336 from the engine control unit (ECU). These codes can be very useful indicators of the problems with the sensors.

In addition, perform a careful visual examination of the sensor and its wiring to spot any physical damage such as the damage resulting from corrosion or wear. Failure of wiring and connector can result in the sensor not working properly. In the end, meter the resistance and the voltage produced using the multimeter. This comparison shows if the sensor works within expected limits according to the manufacturer’s specifications. While checking the voltage signal input while the engine runs, it can identify if the sensor generates an appropriate signal.

Collecting the necessary tools and materials before you replace the position sensor is necessary. Depending on a particular manufacturer’s specifications, this likely includes a wrench set or sockets, a sensor replacement, and possibly a torque wrench. Next, follow a simple step-by-step procedure to help you find and remove the old sensor. Generally, the procedure involves pinpointing specific mounting near the engine’s crankshaft, disconnecting electrical connections, and unbolting the sensor from its mounting location.

When the old sensor is removed, the new one should be installed in a proper alignment with the indicated torque reading in the manufacturer’s instructions. Hereafter, the ECU must be reset to clear all the stored error codes and enable the ECU to identify and use the new sensor. Moreover, test the vehicle to ensure it works suitably and confirm that the replacement sensor has solved the problem.

Here are a few of the preventive maintenance tips.

Practice these preventative maintenance measures for the best results in your crankshaft position sensor’s durability and failure rate. In addition to routine inspection of your vehicle, paying attention to the warning signs and using original parts will contribute to your car’s excellence in performance.

In brief, the crankshaft sensor is one of the main elements responsible for the operation and performance of the engine. This sensor assures accurate position and rotational speed monitoring of the crankshaft, which makes it possible to adjust fuel injection and proper ignition timing, hence efficient combustion and power generation. It’s necessary to fix problems related to the position sensor on time, as they can cause engine problems and even failures. Being alert and proactive will help keep your engine in good shape and extend the lifespan of your vehicle.

By what means is the crankshaft position sensor used in a car?

The crankshaft position sensor continuously sends data to the engine control unit regarding the crankshaft’s position and speed. At the same time, high accuracy is also used for fuel injection and ignition timing.

What is the sign that my crankshaft engine is worn out?

Some of the common symptoms of a failed crankshaft position sensor include engine misfires, rough idling, difficulties in starting, vehicle stalls, or the check engine coming on the display.

Am I able to change the crankshaft position sensor on my own?

Although you can replace the crankshaft position sensor with the right tools and knowledge, you must be technically aware. If you have doubts, take the car to an auto shop mechanic for advice.

Why does the crankshaft position sensor fail?

Crankshaft sensor failure has various causes, including electrical problems like damaged or corroded wiring and mechanical injuries.

Why do the replacement parts for the crankshaft position sensor have to be high in quality?

Replacing the existing parts with high-quality new ones guarantees the engine system’s reliability, durability, and compatibility, reducing the risk of premature failure and ensuring the best performance.

Japanese Used Cars in Canada

Japanese Used Cars in Fiji

Bridgestone and Michelin are the two industry giants of the tire market.

Considering the recent developments in the world order, oil prices have increased significantly over the last decade. During such times, being well-researched about your car fuel tank and its features can be extremely useful in cost-cutting. Knowing about your car’s fuel capacity may not seem too significant at face value, but such a basic factor […]

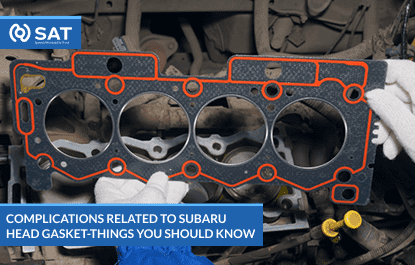

Subaru is widely known for being a highly reliable manufacturer of vehicles that are simultaneously safe and stylish. Because of Subaru Models‘ performance and reliability, these vehicles have a loyal fanbase that swears by them. However, there are some limitations with their boxer engine, and one of the faults in some Subaru vehicles is the […]